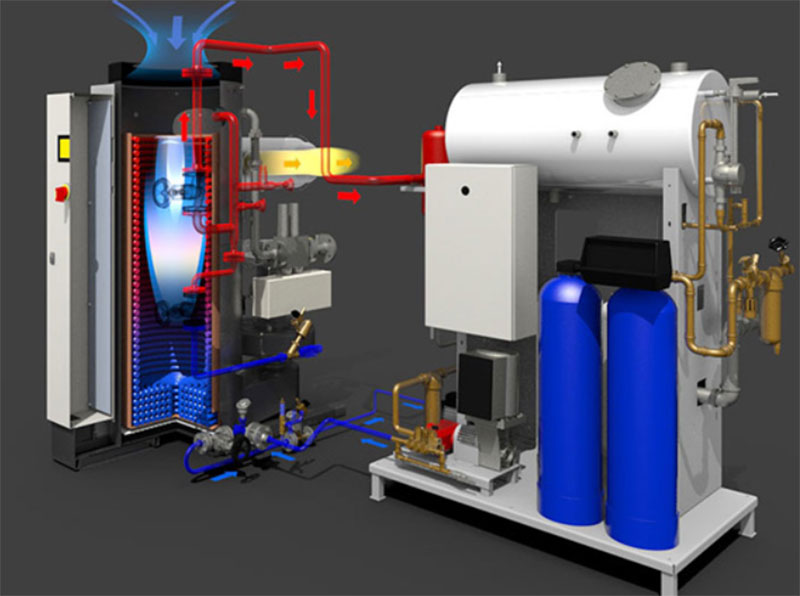

The Universal TC series is our most high performing steam solution. We offer various fuel types, including LPG, natural gas, #2 oil or a dual fuel burner for natural gas and #2 oil. The TC Generators are equipped to serve constant, as well as fluctuating, high steam demands. The touch screen control facilitates operation and gives a bundled overview of current pressures and configurations. All our Generators offer short heat up times and remote operation.

| Frame Size | 4 | 5 | 6 | 7 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacities | Steam output (kg/h) | 500 – 650 | 700 – 850 | 1000 – 1300 | 1500 – 1800 – 2000 | ||||||||

| Heat Output kW | 328 – 427 | 459 – 557 | 656 – 853 | 984 – 1180 – 1320 | |||||||||

| Heat Input kW | 364 – 485 | 510 – 619 | 728 – 947 | 1093 – 1311 – 1457 | |||||||||

| Pressures | Max. WP BarG | 8-14-18-22-29 | 8-14-22-29 | 8-14-22-29 | 8-14-22-29 | ||||||||

| Max. AP BarG | 10-16-20-25-32 | 10-16-25-32 | 10-16-25-32 | 10-16-25-32 | |||||||||

| Measurements (mm) | Height / Width / Depth | 1980 / 930 / 1600 | 2290 / 1160 / 1870 | 2535 / 1260 / 2125 | 2675 / 1380 / 2310 | ||||||||

By using the water tube boiler principle, the CERTUSS technology for generating steam offers maximum safety, reliability and instant availability of high quality steam.

Copyright CERTUSS 2026, All right reserved certuss-asia.com